Food processing is one of the most rigorous industries when it comes to mechanical reliability. Machines that mix, extrude, or convey food must operate continuously, with minimal downtime and zero safety risks. At the heart of most of these machines is a gear motor – a compact, efficient, and robust solution that turns electric energy into precise mechanical motion.

Choosing the right gear motor, however, is not a one‑size‑fits‑all task. It requires careful calculation and an understanding of the process requirements. In this article we break down why accurate gear motor selection matters, walk through the key calculation steps, and look at real‑world food‑processing scenarios where the right motor made the difference.

| Feature | Why It’s Critical in Food Processing | |--------|---------------------------------------| | Compact Size | Equipment often must fit into constrained plant layouts. | | High Power Density | Processes like dough kneading or chocolate tempering demand lots of torque in a small package. | | Reliability | Food safety regulations require equipment that consistently performs without over‑heating or wear. | | Ease of Maintenance | Gear motors can be serviced quickly, reducing plant downtime. |

Because many food‑processing machines rely on predictable torque‑speed profiles, an improperly chosen motor can lead to product quality issues, safety hazards, and costly downtime.

Collecting accurate, real‑world data at this stage sets the foundation for all subsequent calculations.

The basic relationship is:

[ T = \frac{P}{\omega} ]

where (T) is torque (N·m), (P) is power (W), and (\omega) is angular velocity (rad/s).

For a food mixer that requires 20 kW at 250 rpm, the torque is:

[ \omega = \frac{250\times 2\pi}{60} \approx 26.18 \text{ rad/s} \ T \approx \frac{20\,000}{26.18} \approx 764 \text{ N·m} ]

Add a safety margin (typically 20–30 %) to account for spikes and uncertain variables.

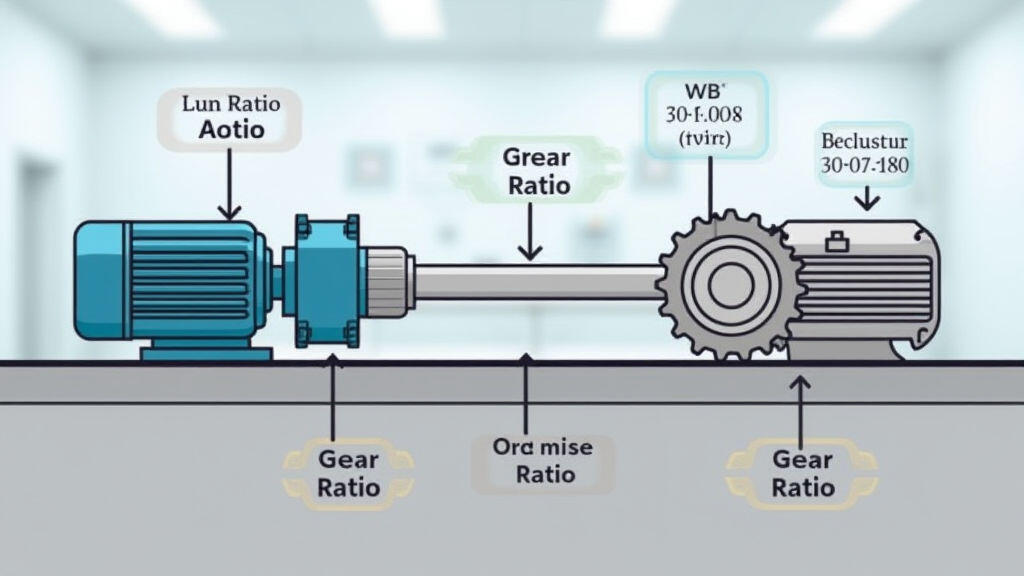

A gear motor delivers a specific base speed (often 150–300 rpm). To match the application speed, choose a gear ratio:

[ \text{Gear Ratio} = \frac{\text{Desired Speed}}{\text{Motor Speed}} ]

If the motor runs at 3 k rpm and the mixer needs 250 rpm, the gear ratio is ~12:1.

Convert the motor’s power rating from current and voltage:

[ P_{\text{motor}} = \frac{V \times I \times \text{Power Factor} \times \eta}{60} ]

Confirm that (P_{\text{motor}}) exceeds the required amplified torque after gear losses (typically 10–15 %).

Food‑processing gear motors must be sealed against food particles and possibly food‑launched debris. Choose an IP rating that matches the plant environment (IP65 or higher for high‑humidity or spray‑rich areas).

A bakery uses a belt‑driven kneader that requires 600 N·m at 55 rpm. The motor selected was a 5 kW, 5 kV, 400 Hz unit rated at 3 k rpm. With a 24:1 gear train, the final speed matches the requirement, while the extra torque headroom handles the intermittent heaviness of dough.

Result: 10 % faster production and fewer motor failures compared to the previous unit.

Tempering demands precise temperature control and smooth rotation to avoid seizing. The line uses a 3 kW motor (2 k rpm) with a 30:1 gear set. The calculation considered a 45 N·m load for constant stirring and added a 25 % safety factor for seizing spikes.

Result: Consistent chocolate quality and a 15 % reduction in energy consumption.

A slicer must rotate at 2000 rpm but stays in a high‑humidity hall. A high‑speed, high‑torque motor (4 kW, 10 k rpm) was paired with a 5:1 gear set. The motor was enclosed in a stainless‑steel shell with an IP68 rating to handle condensation.

Result: 25 % higher throughput and zero contamination incidents.

| Mistake | Consequence | Fix | |----------|--------------|-----| | Underestimating peak load | Motor stall; product defects | Perform a full dynamic load analysis; use a conservative safety margin | | Ignoring environmental conditions | Corrosion; hygiene violations | Select IP-rated enclosures; use stainless‑steel or food‑grade plastics | | Mismatching gear ratio | Inexecutable speed; high vibration | Verify gear ratio with process speed; use simulation tools | | Skipping power factor adjustment | Over‑current; poor energy efficiency | Include power factor correction in calculations; consider variable‑frequency drives |

Modern food plants increasingly adopt digital twins—virtual replicas that simulate machine behavior in real time. By feeding actual torque and speed data into these models, engineers can:

AI algorithms can even suggest the optimal combination of motor rating, gearbox type, and enclosure design with a single click, reducing design cycle time from weeks to days.

Choosing the right gear motor for food‑processing machinery is a precise science that balances torque, speed, safety, and hygiene requirements. By carefully defining the process load, calculating torque and gear ratios, and verifying environmental suitability, engineers can achieve reliable, efficient, and clean operations.

In an era where automation, sustainability, and digitalization drive the industry forward, accurate gear motor selection becomes even more critical. Proper calculation not only prevents costly downtime and product spoilage but also paves the way for smarter, energy‑efficient plants. As AI and digital twins mature, the exactness of motor selection will become integrated into every design workflow, unlocking new levels of performance and safety in food processing.

By investing in meticulous gear‑motor calculations today, plant managers and engineers will secure a competitive edge—delivering high‑quality food products safely, efficiently, and sustainably on a global scale.

Leave A Reply

Your email address will not be published. Required fiels are marked